Find Parts

OUR RUBBER TRACK COMMITMENT

We understand that the replacement of rubber tracks is an inconvenience and disruption to your business – we have backed ourselves with our outstanding TUFFtrac brand which enables us to support New Zealand with rubber that guarantees you superior performance.

With the longest warranty in the market, a “Guaranteed to fit” policy and an outstanding customer response, we commit to remove this interruption to your business and get you back operational with peace of mind that it won’t be happening again anytime soon!

The following brands are just some of what we have in stock, ASV / Terex, Airman, Bobcat, CASE, Caterpillar, Doosan, Eurocomach, Hitachi, Hyundai, IHI / Kato, JCB, Kobelco, Komatsu, Kubota, Morooka, SANY, Sunward, Takeuchi, Toro, Vermeer, Volvo, Yanmar, Yuchai and many more.

BENEFITS OF USING OUR RUBBER TRACKS & PADS;

- Rubber Tracks from 180-500mm wide (0-10-Tonne machines)

- Bolt-on & Clip-on Rubber Pads from 300-700mm wide

- Rubber Tracks available to suit all types of tracked machines

- Guaranteed fitment & reliable performance

- Largest range in stock for nationwide delivery

Excavator Rubber

Experience next generation rubber technology with interlocking core bars preventing stretch and de-tracking. The highest natural rubber content, and offset anti vibration track patterns all reducing wear & tear on your machine and maximising track life. With the most extensive warranty in NZ our rubber tracks deliver serious peace of mind. Supported by the largest stock availability in NZ, and outstanding customer service!

Get a quote

Yes, this can be done on most small excavator models. Some machines require the rollers, sprockets, or idlers to be changed as well, so give us a call with the make and model of your machine, and our friendly staff can advise.

The most common cause of detracking is incorrect track tension. This can be due to lack of attention, stretched or worn rubber track, or lack of maintenance. It could also be caused by the incorrect track being fitted to your machine. Get in touch with our team if you have any questions about detracking, we have the knowledge and support to help!

Every machine has their own standard track size, it is important to know the make, model, and ‘dash’ before that’s all we need and our friendly staff can advise correct track. Sometimes the tracks have the size stamped on the bottom of the track. Numbers are a reference to the Size for example 230x48x70 230 is width, 48 is pitch and 70 is number of links.

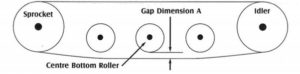

It is important to verify and maintain proper track tension as directed by the machine manufacturer, and this is one of the simplest ways to ensure you get the full life out of your track. Over or under tensioning of a track will cause permanent damage, leading to costly downtime and early track replacement. Loose tracks run the risk of de-tracking, while too tight of a tension magnifies the load and increases wear on the entire undercarriage system. When fitting a new rubber track, the tension must be adjusted to allow a gap from the centre bottom roller to the position on the track where the roller runs – see the diagram below.

This gap varies for different machine sizes as follows:

MACHINE SIZE GAP DIMENSION A

0.75 – 1.5 Tonne 10mm

1.5 – 3.0 Tonne 15mm

3.0 – 6.0 Tonne 20mm

6.0 – 7.5 Tonne 25mm

7.5 – 10 Tonne 30mm

Run the track for 10 revolutions in each direction whilst up in the air then check tension again (as the track will likely adjust during the first few rotations). Run the track normally for 1 hour then check the tension again. After 3 days of operation adjust the tension again and thereafter check it once a week.

CTL Rubber (Compact Track Loader – Sprocket Drive)

The full range of our Heavy-Duty sprocket drive Skidsteer tracks have the next generation rubber compound, track-guard iron core with high-tensile steel cables to ensure no premature failure and are stocked across both islands.

Get a quote

- Drive machine forward to ensure the tracks are evenly tensioned across the entire UC.

- Level and lower the bucket to the ground.

- Raise the front of the machine off the ground approximately 8″ utilizing bucket down pressure.

- Measure track sag by measuring the distance from the inside edge of the track to the bottom edge of the middle mid roller. The clearance for small machines should be 25mm while large machines are 50mm.

Note – We advise you to adjust according to the service manual for the machine. Remember to be safe at all times!

MTL Rubber (Multi-terrain Loader – Lug Drive)

Skidsteer ‘Lug Drive’ machines are extremely severe on rubber tracks – we meet the risk of premature wear head on as New Zealand’s only supplier with continuous steel cording in both our TUFFtrac range.

With traditional Kevlar or Nylon based corded type tracks on the market you can only expect to get 500 hours use. Our new technology of steel cording has been tried and tested and deliver OEM levels of performance at significantly less cost.

Get a quote

- Drive machine forward to ensure the tracks are evenly tensioned across the entire UC.

- Level and lower the bucket to the ground.

- Raise the front of the machine off the ground approximately 8″ utilizing bucket down pressure.

- Measure track sag by measuring the distance from the inside edge of the track to the bottom edge of the middle mid roller. The clearance for small machines should be 25mm while large machines are 50mm.

Note – We advise you to adjust according to the service manual for the machine. Remember to be safe at all times!

Dumper Rubber

Don’t get caught with downtime on these expensive machines! Enquire about our ‘Advanced Plan 365’ indent service giving you peace of mind that we will always have a spare track in stock for your machine removing any risk of downtime. We guarantee you latest design and high performing rubber on call for when you need it.

Get a quote

Bolt-On Pads

Bolt on pads are very popular for excavators which have bolt holes pre-drilled in the steel track shoes. These are available for all machines from 3-25 Tonne.

Get a quote

DRT Warranty

12 Months

M12 – 80 NM.

M14 – 115 NM.

M16 – 175NM.

M18 – 240 NM.

M20 – 340NM.

M22 – 465NM.

They should not delaminate, if they do it will most likely be faulty manufacturing or poor supplier, we guarantee no delamination for life of pad.

It depends on ground conditions, working application and hours worked. For general use on roads, you could expect 3-4 years but with course ballast material such as rail maintenance 1-2 years.

Clip-On Pads

Clip-on type Rubber pads are available for use when you do not have pre-drilled bolt holes in your steel pads. These versatile pads are available for a wide range of different machines from 2-45 Tonne.

Get a quote

DRT Warranty

12 Months

M12 – 80 NM.

M14 – 115 NM.

M16 – 175NM.

M18 – 240 NM.

M20 – 340NM.

M22 – 465NM.

They should not delaminate, if they do it will most likely be faulty manufacturing or poor supplier, we guarantee no delamination for life of pad.

It depends on ground conditions, working application and hours worked. For general use on roads, you could expect 3-4 years but with course ballast material such as rail maintenance 1-2 years.

Chain-On Pads

These pads are different from other types in that they are bolted directly on to the Track chain using track bolts in the same way that a steel track shoe would be bolted on.

Get a quote