Heavy Steel Engineering & Fabrication.

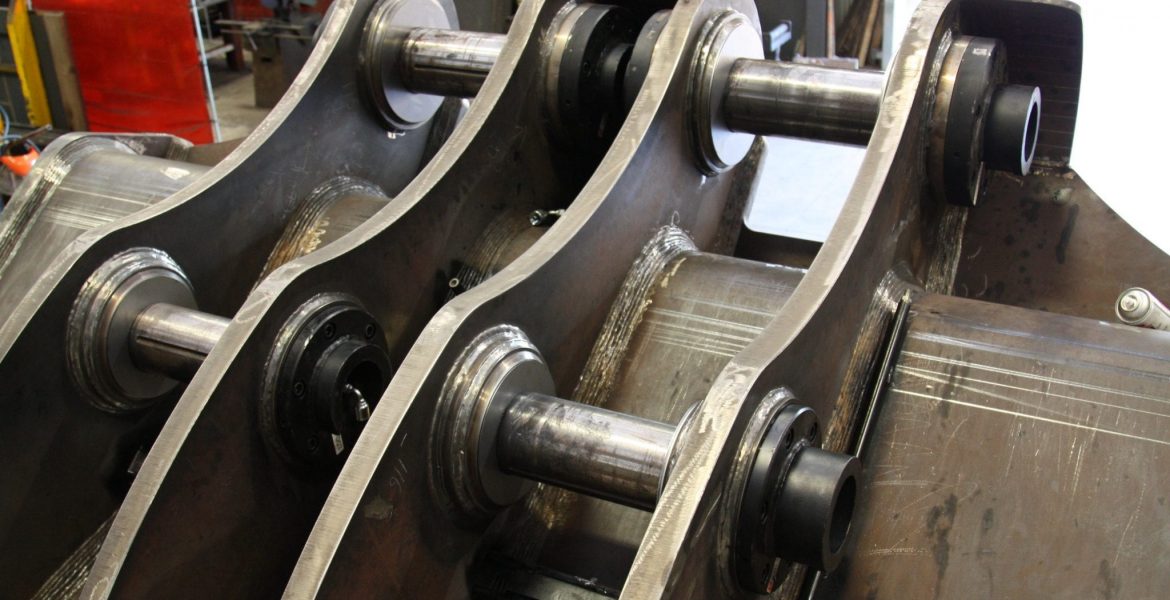

Our large fabrication workshop specializes in heavy steel fabrication using the hardest & thickest Wear Steels.

We weld the big stuff, the hard stuff & and the toughest heat treated, through hardened Wear Steels. Our specialized steel requires specialist welding methods to survive the roughest quarry, mining & forestry environments.

Extreme working conditions need extreme know-how to deliver strong, long lasting, high performing wear parts. Our large team of certified fitter welders are highly skilled at welding High Tensile & Abrasion Resistant steels from 5mm to 140mm thick.

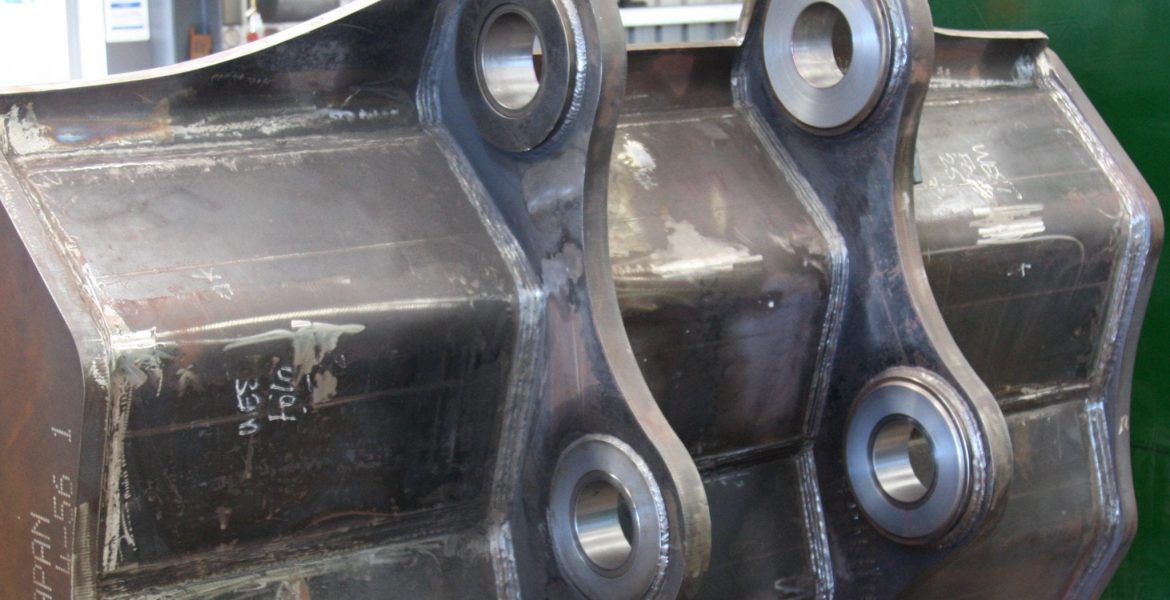

We’ve got the best expertise and heavy engineering experience around, with the skills, the gear & the guys to fabricate large customized wear products such as Buckets, Rippers, Chutes, Hoppers, Screens, Crusher Plates, Grizzly Bars and any other heavy wear related parts & projects.

We’ve mastered the best welding processes & techniques that work, ensuring the correct weld preps, right pre & post heating temperatures, right welding wire grades and proper weld finishing procedures are used to eliminate the possibility of cracking.

We only use the best brands of quenched and tempered, through hardened steels that comply to AS3597 and welding consumables that comply to AS/NZS 1554.4 standards. Our qualified welding staff are certified to AS/NZS 1554.4 and AS2980 welding procedure standards.

We also offer Threaded Stud welding for replaceable wear plates in fixed and mobile crusher applications, which makes it super quick and easy to change-out worn plates, reducing downtime & maintenance costs.

Abrasion Resistant Material (A.R.M) is a Tungsten chip & hard-facing wire mix that can be applied to Bucket teeth, Cutting Edges and other high wear areas to extend the parts service life and performance.