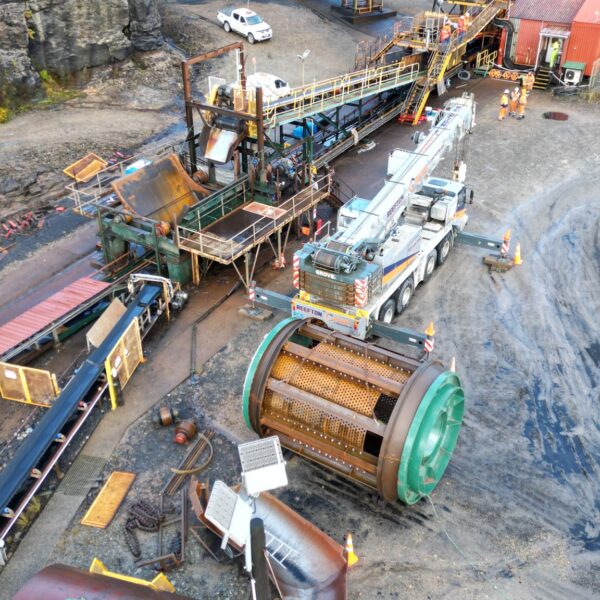

Client: BT Mining (Bathurst Resources)

Location: Stockton Coal Mine processing plant, Ngākawau, West Coast, New Zealand.

Project: Rotary breaker rebuild

Background

BT Mining (Bathurst Resources) approached West-Trak with a need to rebuild a rotary breaker screen at their Stockton Mine coal processing site on New Zealand’s West Coast. As this breaker is a vital part of coal processing, ensuring its durability and reliability was critical for maintaining efficiency and minimising downtime. For more details and to see what BT Mining had to say about this project, check out their LinkedIn post here: https://www.linkedin.com/posts/bathurst-resources

Solution

West-Trak’s Engineering Industry Manager, Avi Walia, worked closely with the BT Mining team to develop a practical and effective solution. Our objective was to replace the worn-out cast wear parts with a new, precision-machined design that met both functional and manufacturing requirements. The redesigned parts allow for easier servicing and maintenance, ensuring that the equipment is not only operationally efficient but also more manageable over its lifespan.

Engineering Capabilities Utilised

The project leveraged West-Trak’s advanced engineering capabilities to execute the rebuild with precision:

- CNC Plasma Cutter – Expertly cut each part to precise specifications, capable of handling thick, wear-resistant steel plates with ease.

- CNC Milling Machine – Provided high-accuracy countersinking to ensure secure assembly and longevity of each component.

- 500T Press Brake – Enabled the precision bending of each plate to the exact angles required for a seamless fit within the rotary breaker.

Get in touch with the West-Trak team for your wear plate and engineering projects!

Call 0393 069 10

Email sales@west-trak.co.nz