Do you need your steel plate machined?

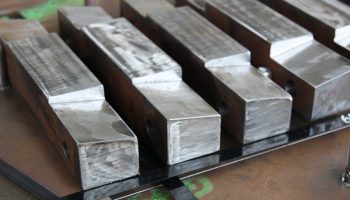

Our team of highly skilled fitter turners & machinists can shape the hardest wear steels into your required part.

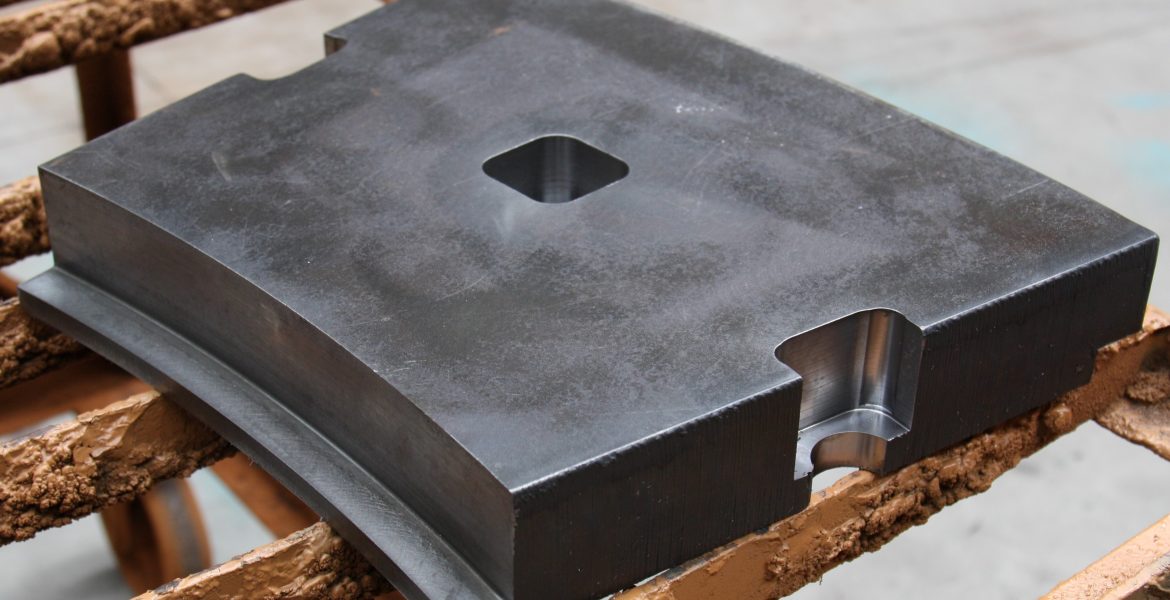

With our large CNC machining centers and years of fitter turning experience, we offer a wide range of drilling & machining services for all grades & thicknesses of steel plate. Our engineers are master craftsmen, skilled in fitting, turning, welding, tool making and mechanical problem-solving.

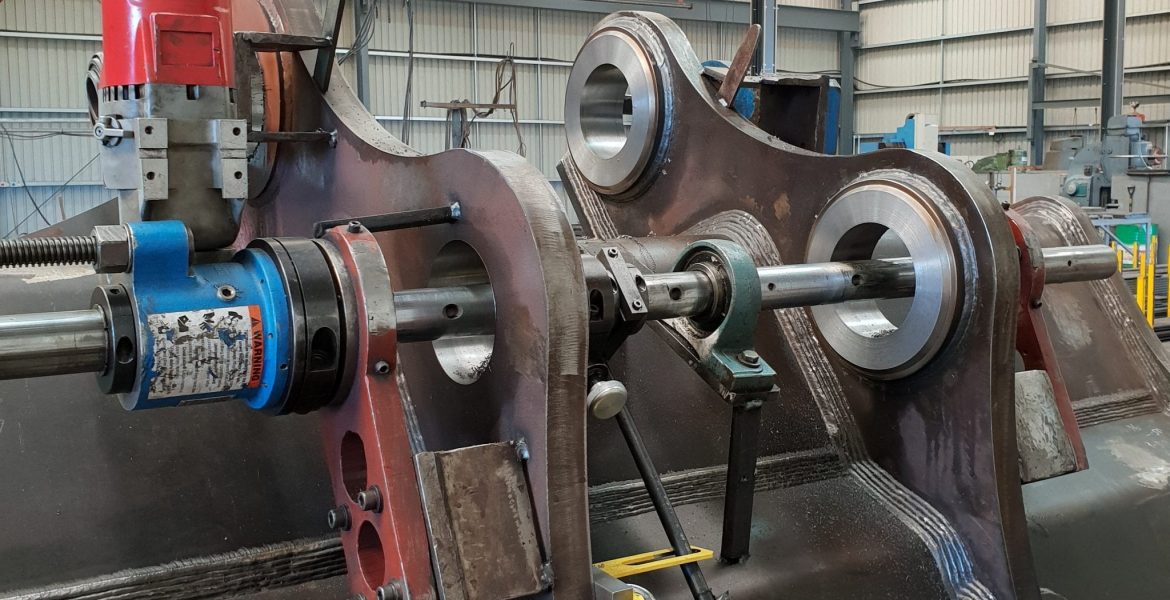

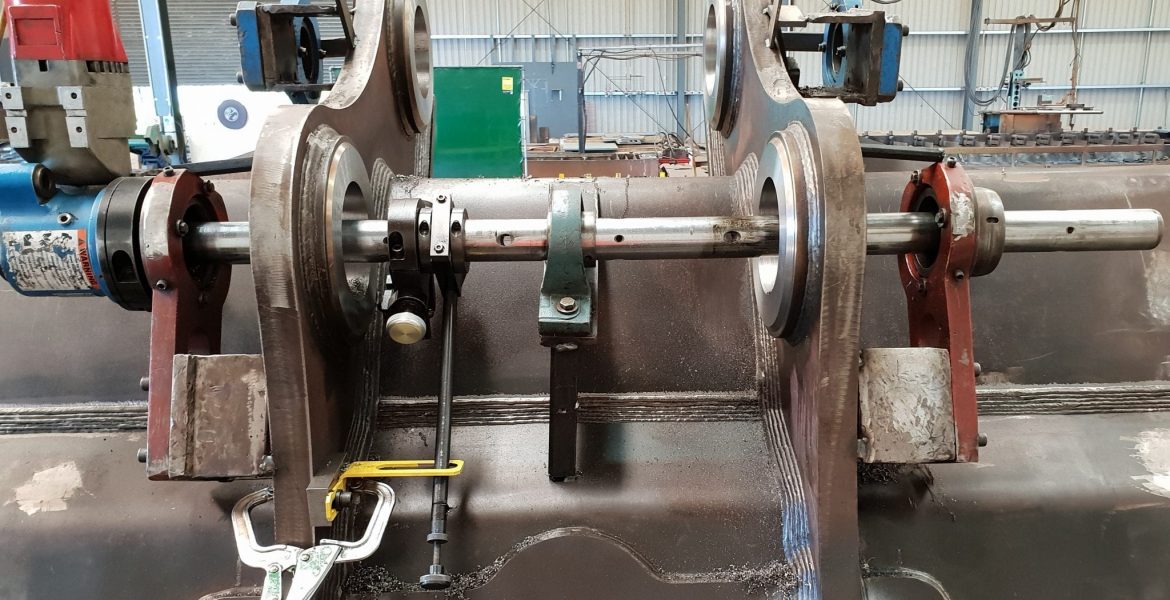

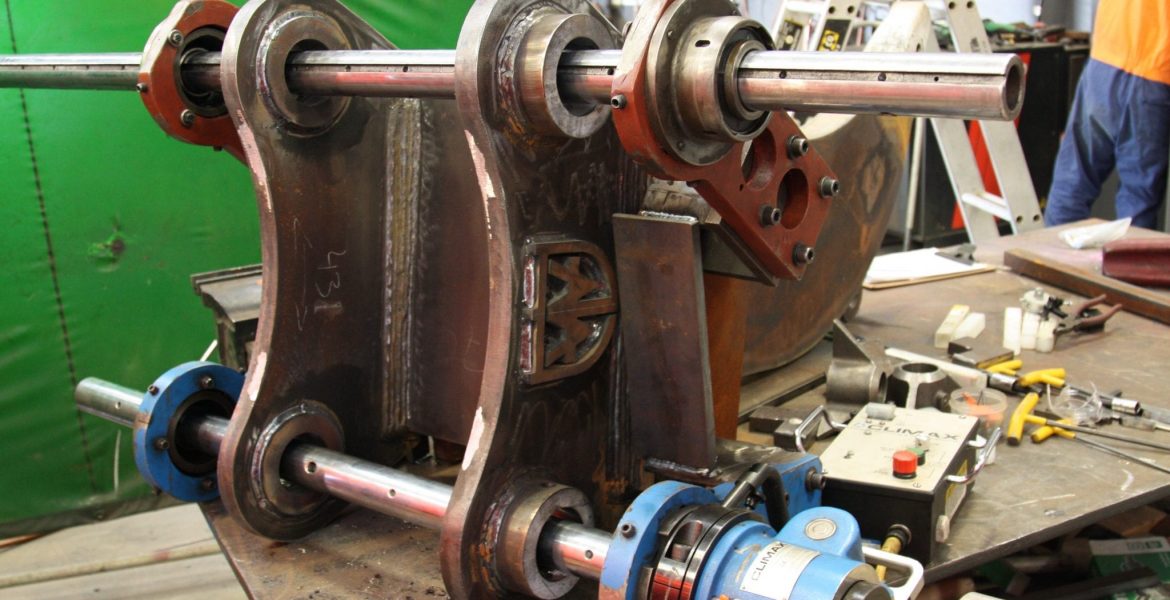

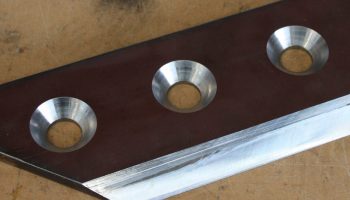

Our work includes hole building and boring, joint/pivot repairs, customized machining and lathing jobs. We work with the hard stuff! Drilling, Milling, Tapping, Line Boring & Lathing the toughest, through hardened wear steels in the world.

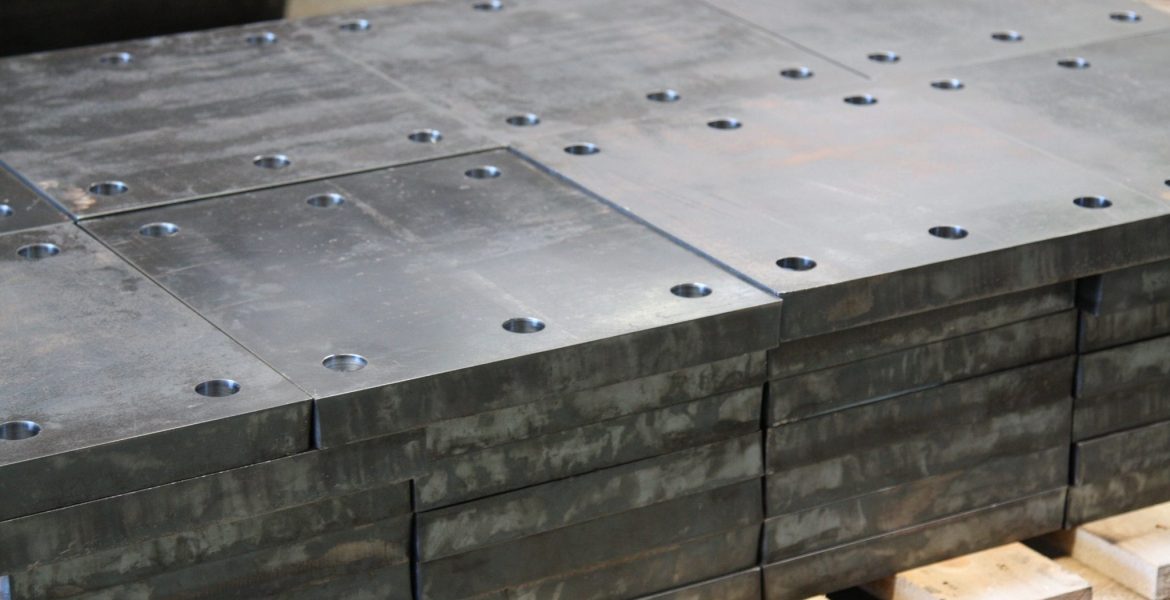

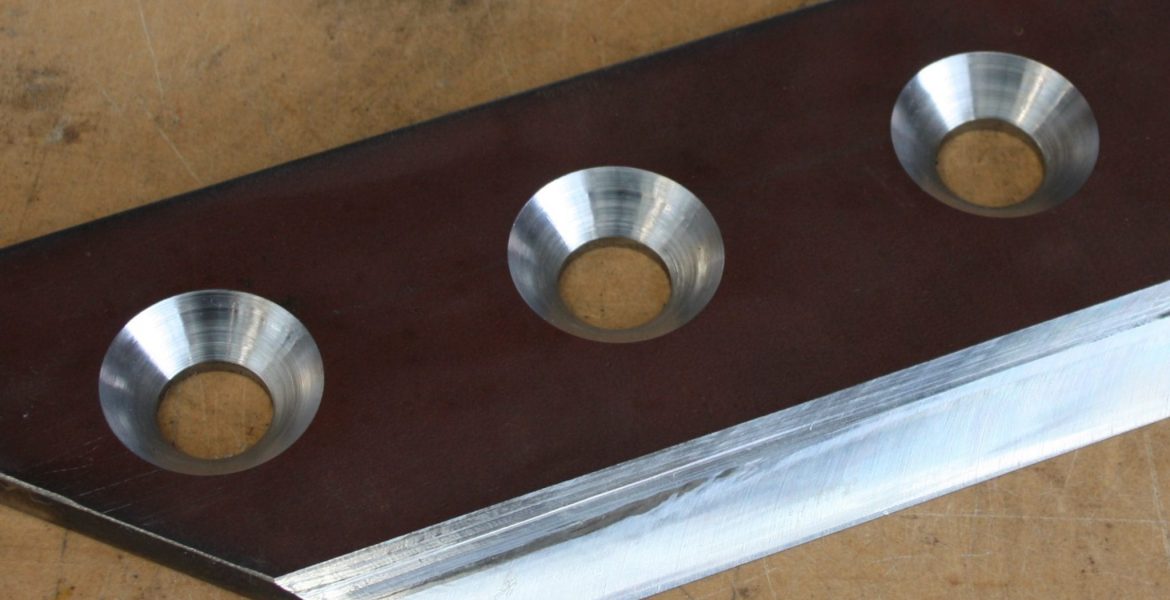

Using specialized tungsten tip tooling & techniques we can machine G450 & G500 grade Abrasion Resistant Steels with ease. We have a huge range of tools on hand to suit every hole type including drilled holes, threaded holes, countersunk holes, counterbored holes, cap screw holes, plow bolt holes & keyway holes!

You’ll get high quality workmanship, fast turnaround times with guaranteed form, fit & function. Our professional engineers & mod-con machinery can produce the tightest tolerances & most precision accuracy.

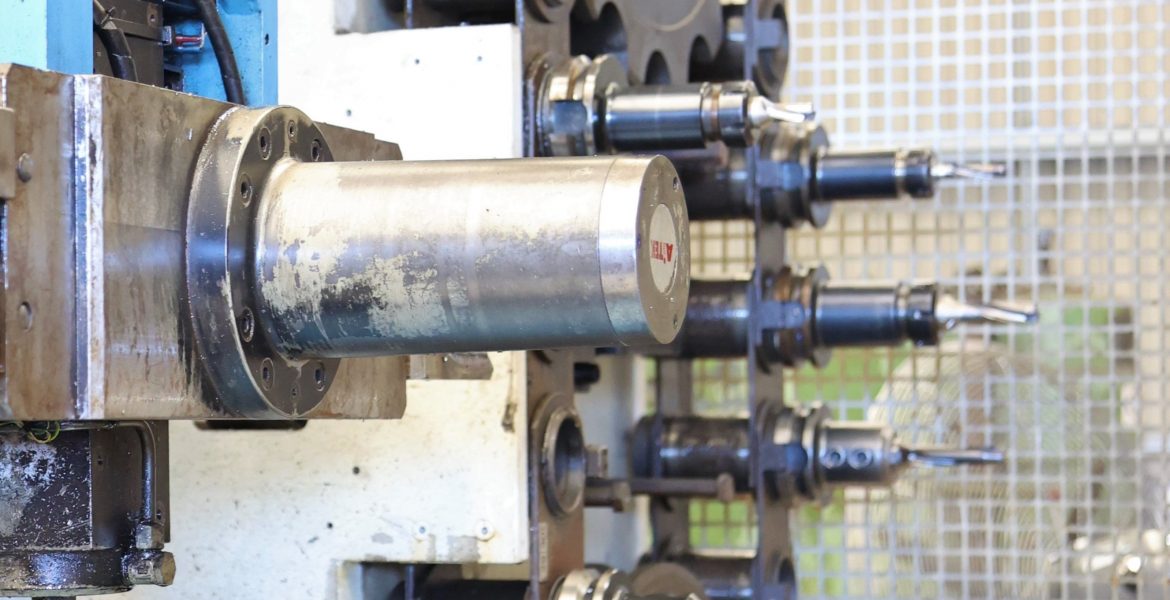

Our Machines;

- 5-axis CNC Machining Center with a 30 piece tool changer & 4m long x 1.2m wide bed

- 4-axis CNC Machining Center with a 60 piece tool changer & 2m long x 0.7m wide bed

- CNC Horizontal Lathe with a 3m travel bed

- Line Boring Unit with 450mm ID boring capacity

Our Tooling;

- Drilled holes: 5mm to 75mm Ø

- Counterbored holes: 10mm to 75mm Ø

- Countersunk Plow Bolt holes: 1/2’’ to 1.3/8’’ Ø

- Cap Screw holes: 10mm to 30mm Ø

- Keyway holes: 10mm – 30mm Ø

- Threaded holes, 10mm to 30mm Ø